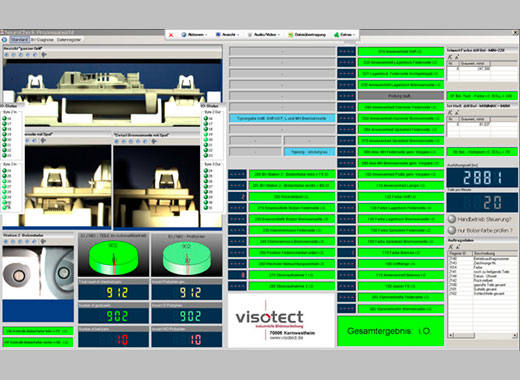

Checking of roof handles for cars

A special-purpose machine assembles a complete roof handle from its individual parts. The image processing (IP) checks ten elements for presence,

four for correct type, eight elements for correct color and three for correct assembly. A total of 25 tests are carried out on each component.

The IP also receives via fieldbus the results of 11 further tests which are carried out by sensors in the assembly machine. These are visualized

on the automatic screen of the image processing and the results are kept in the statistics of the IP.

Particularities:

The component colors sometimes differ only in nuances that are almost indistinguishable by eye.

Extensive statistical functions:

The test results for each individual component are recorded in an Excel-readable csv file. The file also contains counters for the

total number of tested parts, the OK and NOK parts and counters for the number of bad parts for each test criterion.

Measurement of components for intensive care medical devices

Touchscreen panes of patient monitoring devices in intensive care medicine are mounted in a plastic frame by robots. In order to compensate for

component and position tolerances, each touchscreen pane and each frame is measured by the image processing system before assembly. The measured

values are transferred to the robot controller which corrects the position values for the robot control accordingly.

Particularities:

A line camera is mounted on a robot arm. This records the component contours during robot movement, and the image processing system uses

them to calculate the correction values for the robot positions.

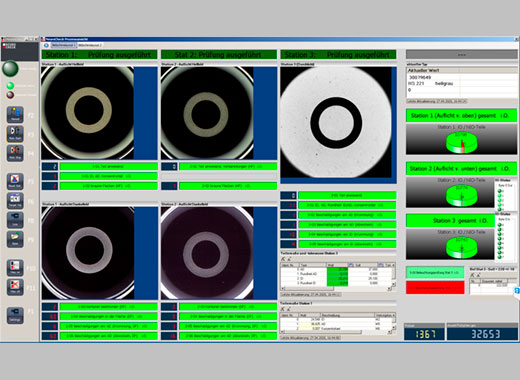

Checking Teflon sealing rings for fuel injection pumps in cars

A special-purpose machine fits spring elements into specially designed sealing rings made of Teflon for car injection pumps.

The image processing system checks the raw parts for the sealing rings before assembly, the spring elements and the finished parts after

assembly for a total of 27 parameters at 6 stations. Each station has a matrix camera and two illuminations. Different test criteria are

visible with the different lighting. The lights are switched alternatively, and one picture is taken with each light, so that 12 pictures

are taken and evaluated for each part. The entire system runs with a cycle time of approx. 4 seconds.

Particularities:

The multitude of test criteria.

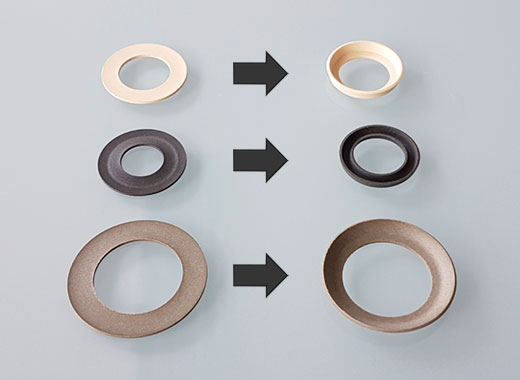

Checking thermoformed sealing rings

A special-purpose machine converts circular blanks by thermoforming into elements with a three-dimensional contour.

The image processing system checks the raw parts for various parameters and measures the diameter of the finished parts.

Particularities:

Diameter measurement with accuracies in the 1 / 100mm range. To do this, telecentric lenses and lighting are used.

Assembly inspection on car bumpers

Bumpers of modern cars are equipped with a considerable number of add-on parts such as trim elements, distance sensors, etc., and there are

a large number of variants. Each bumper is individually equipped with attachments based on its component number. The fully assembled bumper

is passed (partly with a driverless transport system) into a test cell, in which image processing is used to check whether all elements have

been installed in accordance with the specifications.

Particularities:

Camera mounted on the robot arm.

The target specifications for each part to be inspected are passed on to the image processing system by the higher-level controller immediately

before the start of an inspection cycle.